Recently, 伟德软件下载安装手机版 successfully delivered three sets of HA27000/peg turnkey projects to Honsen Beverage Group, with smooth commissioning at its bases in Hangzhou, Tianjin, and Guilin. The projects enable end-to-end automated operations from raw materials to finished products, showcasing Haitian’s technological strength in the field of extra-large injection molding equipment. This milestone also marks a solid step forward in the collaboration between the two parties in the logistics equipment sector.

At the handover ceremonies, representatives from both sides were present, including Mr. Xu Bin, Deputy General Manager of Haitian’s Global Industry Line; Mr. Yu Feng, Manager of the Logistics Industry Line; Mr. Chen Yihan, General Manager of Haitian Hangzhou Sales Company; Mr. Chen Yirong, Regional Sales Manager; and Mr. Kuai Yue, Regional Manager of Haitian Smart Solutions. From Honsen Beverage Group, attendees included Mr. Jiang Chengming, Head of the Hangzhou Smart Pallet Project; Mr. Gong Yongbing, Production Section Chief of Guilin Plant; and Mr. Wu Ziwan, Production Section Chief of Tianjin Plant. Together, they witnessed the successful delivery of this important cooperation achievement.

Since the project was launched, both parties have attached great importance and worked closely together. The Hangzhou base took the lead, completing equipment delivery and commissioning on August 13, followed by the Tianjin and Guilin bases on September 1 and September 2 respectively. The smooth and efficient rollout across all three sites highlights Haitian’s outstanding integration capability and delivery efficiency.

This project was jointly executed by 伟德软件下载安装手机版 and Haitian Smart Solutions, delivering a comprehensive turnkey solution that covers both equipment and full plant planning. The delivered HA27000/peg turnkey projects are dedicated to the efficient production of pallets, integrating key modules such as automated part removal, precise block insertion, intelligent labeling, and high-speed palletizing, along with complete planning and implementation of utilities including water, electricity, and air. The result is a truly end-to-end solution that ensures rapid commissioning, stable operation, and a high level of integration, enabling Honsen Beverage to significantly enhance both efficiency and smart manufacturing capabilities.

The successful delivery across three sites demonstrated not only smooth production start-up and stable line performance but also validated the professionalism and forward-looking collaboration between the two companies. As the equipment supplier, 伟德软件下载安装手机版 leveraged its proven turnkey engineering expertise to provide Honsen Beverage with a fully integrated solution, facilitating the automation upgrade of its pallet production lines. Looking ahead, both parties will continue to focus on practical production needs, driving the industry toward greater efficiency and stability with reliable equipment performance and precise project execution, while offering a replicable model for future line upgrades.

The post Haitian Delivers Turnkey Pallet Line to Honsen Beverage appeared first on 伟德软件下载安装手机版.

]]>In the first half of 2025, Haitian International increased revenue by 12.5% to RMB 9.0 billion (approx. USD 1.26 billion). Sales volume rose by 8.8% to 29,438 machines, already surpassing half of last year’s total. Overseas business grew strongly by 34.7%.

Hong Kong, August 18, 2025 – Haitian International, one of the world’s leading manufacturers of plastic injection molding machines, has announced its interim results for the first half of 2025. Revenue reached RMB 9,018.3 million (approx. USD 1.26 billion), driven by robust global demand and strong performance across key product series.

Of particular note, sales volume increased to 29,400+ machines (+8.8%), already exceeding half of the company’s full-year total of 53,000 units in 2024. Overseas sales rose significantly by 34.7% to RMB 3,817.7 million (approx. USD 534.5 million), underscoring the company’s successful global expansion.

The servo-hydraulic Haitian Mars Series (toggle) and Haitian Jupiter Series (two-platen technology) proved to be the key growth drivers in the first half of the year, particularly supported by demand from consumer goods, household appliances, and the rapidly expanding new energy vehicle (NEV) sector. The electric segment also showed clear gains: Zhafir Plastics Machinery, a pioneer in electric solutions, together with the new Niigata brand, increased both sales volume and revenue. With 2,044 machines delivered (+4.6%) and revenue of RMB 1,072.2 million (approx. USD 150.1 million, +5.3%), the electric series confirm their growing importance within Haitian International’s portfolio.

“Through continuous technological innovation, we are developing machines that are even more energy-efficient and intelligent, offering our customers tailored solutions with high added value,” said Zhang Bin, Executive Director and CEO of Haitian International.

Looking ahead, Haitian is pursuing a consistent internationalization strategy. New production sites in Japan, Serbia, and India are being established to strengthen delivery capabilities in key markets and enhance local value creation. “Our strategy is focused on supporting customers worldwide in the best possible way. With new plants in Japan, Serbia, and India, we are enhancing our local presence, securing supply chains, and responding even faster to market demand,” Zhang added.

About Haitian International

Haitian International is a global leader in the development and manufacturing of electric and servo-hydraulic injection molding machines. With over 53,000 machines delivered in 2024 and a strong brand portfolio (Haitian, Zhafir, Niigata), the company covers nearly all areas of plastics processing. Haitian has nearly 60 years of manufacturing expertise, full in-house production of all key components, and a strong global footprint with six international headquarters and a presence in over 130 countries.

Footnote: Exchange rate as of August 2025: 1 RMB ≈ 0.14 USD.

The post Haitian International Increases First-Half Revenue by 12.5% appeared first on 伟德软件下载安装手机版.

]]>From August 1 to 2, the Haitian International Medical Industry Technology Center Open Day was successfully held in Suzhou, attracting over 200 industry experts, partners, and customer representatives. With the theme “Breaking Boundaries, Creating Value Together,” the event focused on technological innovation and collaborative applications in the field of medical injection molding. Through cutting-edge technology forums and live machine demonstrations, Haitian International showcased its high-end solutions for medical manufacturing.

At the beginning of the event, Mr. Zhu Hongguo, Director of the Medical Industry Division, delivered the opening speech. He welcomed all guests and shared insights on the technical challenges and collaboration opportunities in the medical sector.

Over the course of the two-day event, six thematic forums brought together cutting-edge topics in medical injection molding. In-depth discussions covered Haitian’s integrated PVC solutions for medical applications, the role of high-precision molds in emerging product trends, smart manufacturing solutions from Haitian Smart Solutions for the medical industry, the development outlook and market strategies in the insulin infusion sector, how RJG supports OEE improvement in medical injection molding, and how fundamental logic in polymer materials drives functional breakthroughs in medical applications. The sessions sparked active engagement and insightful questions from attendees.

At the event, Haitian International showcased eight precision injection molding solutions tailored for medical applications, covering the full spectrum of demands from micro components to large-scale devices. The demonstration area attracted a constant stream of visitors eager to observe the machines in action.

Notably, the fifth-generation Zhafir series features advanced precision molding technologies such as PDC (Precision Dosing Control), IFC (Inertial Filling Control), and OFC (Optimal Force Control). These innovations significantly enhance production stability and deliver outstanding performance in high-precision micro molding for medical applications, earning unanimous praise and recognition from attendees and industry experts alike.

Zhafir VE600V

Equipped with multi-cavity precision injection technology, this solution achieves 96-cavity molding of 0.02g PP protective caps with a cycle time under 20 seconds, meeting the demands of high-efficiency, large-scale production for miniature medical parts.

Zhafir VE900V

Utilizing micro-precision molding technology, this machine delivers stable 4-cavity production of 0.65g PBT insulin pen screw rods with a 15-second cycle time, addressing the high-precision requirements of small medical components.

Zhafir VE1200V

Powered by micro-precision molding technology, this solution completes 4-cavity molding of 2.8g PBT insulin pen plungers and barrels within an 18-second cycle, ensuring precision and efficiency.

Zhafir VE1500V

A specialized solution for medical-grade PVC, designed for 48-cavity production of 2.08g Y-type 3-way connectors used in blood transfusion sets. With a 20-second cycle time, it enhances the sealing performance of infusion systems while enabling high-throughput manufacturing.

Zhafir ZE1900V

With an 8+8 cavity design, this solution produces AS filter housings (top and bottom), each weighing just 2.5g, within a 20-second cycle—enabling precise and efficient matching for filtration devices.

Zhafir ZE2300V

Designed for high-efficiency multi-cavity molding, this system delivers 48-cavity production of 0.58g PP stop rings with a 10-second cycle time, meeting the demands of mass production for micro components.

Zhafir ZE3000V

Live on site, this machine demonstrated the molding of 32-cavity, 20ml syringe barrels using a full hot runner system with dual valve gates. Each part weighs 5.35g and is produced within a 12-second cycle, ensuring excellent precision and concentricity.

Haitian MA2100V/F

Featuring deep-cavity multi-cavity technology, this solution enables high-speed molding of 24-cavity, 1.96g PP syringe barrels in just 10 seconds, offering an optimal balance of performance and cost-efficiency.

This Open Day not only served as a platform for technical exchange within the industry, but also fostered full-spectrum engagement by seamlessly integrating expert discussions, solution showcases, and ecosystem collaboration. It highlighted the broader possibilities of medical injection molding technology.

Although the curtain has closed on the Open Day, the shared vision of “Breaking Boundaries, Creating Value” is now taking root as a new starting point for action. We look forward to seeing these solutions light up more customer production lines in the future. Driven by innovation, Haitian International will continue to join hands with its partners to push the boundaries of medical injection molding—transforming technological breakthroughs into real momentum for industry advancement.

The post 伟德bv国际体育官网 appeared first on 伟德软件下载安装手机版.

]]>On July 9, Haitian Indonesia officially opened its Semarang Application Center. Over 50 key local customers and partners gathered to witness this milestone in strengthening regional technical service capabilities.

The newly launched Semarang Application Center integrates mold testing services, a high-turnover spare parts inventory, and ready-stock injection molding machines—offering customers a one-stop solution for immediate testing, verification, and delivery. As a key initiative in Haitian’s Southeast Asia strategy, the center aims to energize Indonesia’s plastics industry with fast response and full lifecycle support.

At the opening event, two flagship machines became the center of attention. The Haitian MA3800H/PRO demonstrated the efficient production of takeaway containers, earning high praise for its stable injection performance and energy-saving design. Meanwhile, the MA1600GII showcased its precision and operational excellence through a dry cycle display. Guests were drawn to the live demonstrations, many stopping to watch and capture the moment with photos.

At the event, Mr. Tao, General Manager of Haitian Indonesia, delivered a speech outlining the company’s development strategy for the Indonesian market. He emphasized that the Semarang Application Center will serve as a key link in leveraging Haitian’s strengths in technology, service, and innovation. With a more professional approach and faster response capabilities, Haitian Indonesia aims to become a vital bridge—connecting with customers, serving the market, and continuously creating value for the local plastics manufacturing industry.

Following that, Mr. Luo Jun, Manager of the Semarang Center, reviewed the development journey of the service site and highlighted the current team’s strengths. The center is now equipped with a professional technical support team and a high-turnover spare parts inventory. It also offers a three-year free maintenance policy for injection molding machines and a two-year free parts replacement policy. In addition, the center will provide customers with professional training in equipment maintenance, servicing, and process optimization.

After the opening ceremony, the Haitian Indonesia team engaged in in-depth discussions with customers on market trends, industry needs, and process optimization. The launch of the Semarang Application Center marks a further step in strengthening Haitian’s localized service network in Indonesia. Haitian remains committed to continuous investment, leveraging technology and service excellence to build an efficient service network across the country—working hand in hand with Indonesian partners to shape the future of the plastics industry.

The post Haitian Semarang Center Opens to Boost Tech Support in Indonesia appeared first on 伟德软件下载安装手机版.

]]>Senior Leadership Gather to Witness a New Beginning

On May 16, 2025, Haitian Group and Haier Smart Home Co., Ltd. (hereinafter referred to as “Haier Smart Home”) officially held a signing ceremony for a global strategic cooperation agreement at the Haier Ecosystem Brand Center. This event marks a new milestone in their 30-year partnership, expanding into a broader global strategic collaboration.

Mr. Zhang Jianfeng, Chairman and President of 伟德软件下载安装手机版 Group, attended the signing ceremony together with Mr. Ye Jingbo, Assistant President and General Manager of the China Region, Mr. Mao Yucheng, General Manager of the North China Region, Mr. Chen Bing, General Manager of the Qingdao Branch, and Mr. Chen Yilong, Deputy General Manager of the Qingdao Branch. From Haier, the event was graced by Mr. Li Huagang, Senior Vice President of Haier Group and Chairman & President of Haier Smart Home, Mr. Li Yang, Vice President and Global Head of Procurement at Haier Smart Home, Mr. Liu Xiaobo, General Manager of the Washing Appliance Supply Chain, and Ms. Wang Rongmei, General Manager of Indirect Procurement. At the ceremony, Mr. Zhang Jianfeng and Mr. Li Huagang signed the strategic cooperation agreement on behalf of Haitian and Haier respectively, officially launching a new chapter in their partnership.

Powerful Partnership: Focusing on Smart Manufacturing and Customized Services

As leaders in the field of equipment manufacturing and smart home ecosystems, Haitian and Haier will deepen their integration of advanced technologies such as intelligent manufacturing, big data, and artificial intelligence. The partnership aims to explore customized services that meet full-scenario user demands and to jointly build a co-creative and mutually beneficial ecosystem. Haitian will provide Haier with world-class technical support and efficient supply chain services, leveraging its global network to support Haier’s localized smart manufacturing and agile response in overseas markets. Additionally, the two parties will cooperate on talent development, jointly cultivating skilled professionals in intelligent manufacturing to accelerate the implementation of ecosystem capabilities.

Three Decades of Trusted Collaboration,Advancing Global Ecosystem Co-Creation

Since Haier purchased its first Haitian injection molding machine in 1995, the two companies have built a close partnership spanning three decades. To date, Haitian has delivered over 500 high-performance injection molding machines to Haier and has been recognized with multiple honors, including the “Global Partner Award.”Going forward, Haitian will continue to support Haier in building intelligent and connected factories, and in establishing a digitalized and intelligent production system. This upgraded strategic collaboration will further integrate the global resources of both parties and lay a solid foundation for jointly building a “one-stop intelligent manufacturing service chain” in international markets. In the future, Haitian and Haier will deepen their cooperation and explore new paths in intelligent manufacturing and customized services—delivering higher-quality, more efficient experiences to customers around the world.

The post Haitian x Haier | Global Strategic Cooperation appeared first on 伟德软件下载安装手机版.

]]>In April 2025, Haitian Brazil received the “Best Partner” award from Midea Industrial Brazil (hereinafter referred to as “Midea Brazil”) in recognition of its efficient execution and comprehensive service capabilities in smart manufacturing projects. This recognition not only reflects the strong collaboration between the two companies, but also highlights the growing global strength of Chinese manufacturing enterprises.

Amid the wave of globalization, Chinese manufacturers are breaking new ground in overseas markets with solid capabilities. As a leading brand in injection molding equipment, Haitian International has joined forces with home appliance giant Midea Group to deepen their presence in the Brazilian market. Powered by technological innovation and localized strategy, the two companies are jointly opening a new chapter in South America’s industrial development.

Since its establishment in 2004, Haitian Brazil—one of Haitian International’s wholly owned overseas subsidiaries—has been deeply rooted in the Brazilian market, focusing on high-performance products and efficient, localized services. Covering a land area of 12,000 square meters with 4,600 square meters of building space, the company currently operates with 16 regional sales representatives, 22 internal service teams, 10 regional service teams, and over 20 distributors. This structure forms a comprehensive service network that supports over 1,500 customers across South America. From complete machine supply to fully integrated system solutions, along with extensive mold testing and application support, Haitian Brazil stands out as the trusted partner for premium manufacturing projects.

Backed by Midea Group’s global strategy, Midea Brazil has established a new manufacturing facility in Pouso Alegre. With an investment of over RMB 700 million, the plant covers 270,000 square meters, including more than 70,000 square meters of built-up area, and features two core business units focused on washing machines and refrigerators. The factory integrates a wide array of digital production technologies and cutting-edge innovations. The first batch of smart refrigerators began production in July 2024, followed by the trial production of top-loading washing machines in August 2024, both of which were simultaneously launched to the market. Serving not only the domestic market, these products are also exported to other countries across South America, positioning the facility as a major hub for smart appliance supply in the region.

The partnership began in early 2023, when Haitian Brazil was invited to bid for Midea’s Brazil refrigerator project, led by its Hefei division. In 2024, as Midea’s washing machine division expanded into the Brazilian market, Haitian Brazil—leveraging its high-performance equipment, swift service response, and two decades of local expertise—was selected as a strategic partner.

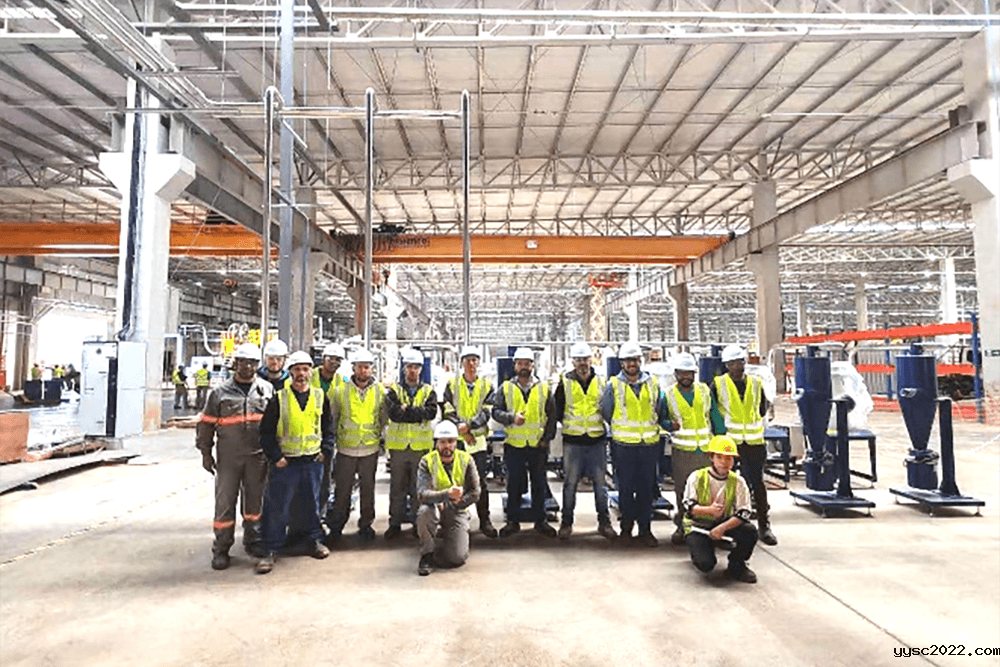

Faced with the demanding turnkey delivery of Phase I of Midea Brazil’s new factory, Haitian Brazil swiftly formed a dedicated technical service team to work in close collaboration with Midea’s project group. From the moment the machinery and utility systems—including water, electricity, compressed air, and raw material supply—arrived on site, Haitian’s team was fully engaged in intensive installation and implementation.

Through ongoing collaboration, real-time adjustments to construction plans, and continuous technical refinement, the two teams worked tirelessly for over three months. This led to the successful completion of Brazil’s first locally executed turnkey project, integrating injection molding, centralized material feeding, and utility systems—setting a new industry benchmark for efficiency. The achievement showcased Haitian Brazil’s technical strength and laid a solid foundation for Midea’s rapid expansion in the Brazilian market.

During mold testing, trial production, and the gradual ramp-up of low-volume output, Haitian Brazil provided full on-site support—from equipment commissioning and technical assistance to multiple rounds of employee training—ensuring stable and reliable line operation. As a result, Midea’s washing machine project achieved mass production ahead of schedule. The product’s outstanding value and smart features quickly captured the Brazilian market, with order volumes continuing to rise.

By 2025, Midea’s Brazil factory had achieved highly efficient dual-shift operations. Haitian’s injection molding machines and associated sub-projects stood out for their high precision, ease of use, and low failure rate—along with the Haitian service team’s consistent follow-up and proactive support—earning unanimous recognition from both Chinese and Brazilian teams at Midea. Less than three months after the Phase I delivery, Midea Brazil invited Haitian Brazil to initiate Phase II planning and began early deployment for Phase III and IV, signaling a deeper level of cooperation.

This collaboration has not only enabled Haitian Brazil to achieve breakthroughs in technology and service within large-scale integrated projects, but also accelerated Midea’s rapid expansion across the South American market. From early-stage alignment to deep mutual trust, the two companies have forged a strong partnership and lasting friendship—injecting powerful momentum into the growth of South America’s smart manufacturing ecosystem.

The “Best Partner” award from Midea Brazil is a strong endorsement of Haitian Brazil’s technical expertise and commitment. Moving forward, the two sides will continue to deepen cooperation in intelligent manufacturing and green production, leveraging innovation to drive the upgrading of South America’s home appliance industry and jointly writing a new chapter in the globalization of Chinese intelligent manufacturing.

The post Haitian Brazil Wins Midea Brazil’s “Best Partner” Award appeared first on 伟德软件下载安装手机版.

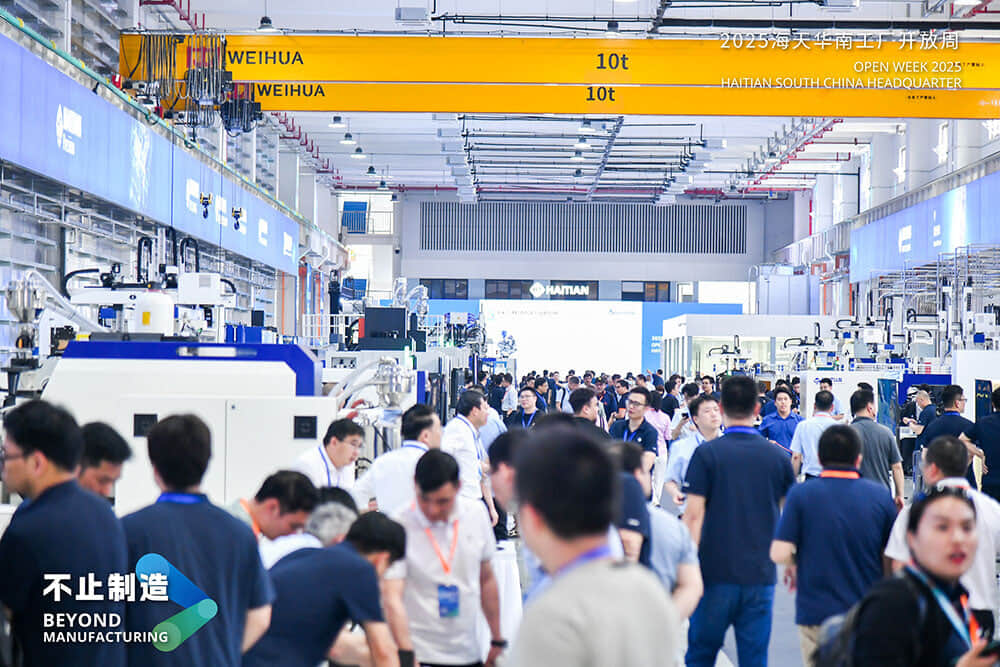

]]>From April 15 to 18, the Haitian South China Headquarter Open Week was held with great success. Under the theme of “Beyond Manufacturing,” the event attracted over 3,000 customers, partners, and investors from more than 20 countries, gathering at Haitian’s South China Headquarter in Shunde, Foshan to envision the future of high-quality development in the smart equipment industry.

At the welcome ceremony on April 17, Mr. Zhang Jianfeng, CEO of 伟德软件下载安装手机版 Group, delivered the opening address on behalf of the Haitian Group. He introduced Haitian’s comprehensive industrial chain and reaffirmed the Group’s strong commitment to deeply cultivating the South China market, aiming to provide customers across the Greater Bay Area with more comprehensive and high-quality services and support.

Opening speech by Zhang Jianfeng, President of 伟德软件下载安装手机版 Group

Mr. Shen Li, General Manager of Haitian South China, further unveiled the strategic significance of the South China Headquarters. As one of Haitian’s two major domestic hubs, the South China Headquarters spans over 500 acres with a planned investment of 5 billion RMB, featuring multiple advanced factories already in operation. By leveraging fully intelligent production lines, leading automation equipment, and a “1+N” management model, it has established a complete closed-loop ecosystem covering standalone machine delivery, integrated solutions, production, and talent development. It serves as a vital engine for Haitian’s leapfrog development in the Pearl River Delta.

Speech by Shen Li, General Manager of Haitian South China

Mr. Xiang Linfa, General Manager of Haitian Group Global Business Division, reviewed Haitian’s overseas expansion journey and presented the Group’s current overseas industrial and ecological network. He emphasized that Haitian remains firmly rooted in the machinery and equipment industry, focusing on customer application scenarios and continuously creating and extending value through outstanding products and a robust ecosystem, helping customers succeed in their respective markets.

Speech by Xiang Linfa, General Manager of Haitian Group Global Business Division

The Open Week featured a series of carefully curated activities, offering guests a comprehensive showcase of smart manufacturing excellence.

During the factory tours, guests visited the production workshops at the South China Headquarter, experiencing Haitian’s ultra-modern manufacturing syste, leaving a strong impression of Haitian’s production capabilities.

Meanwhile, cutting-edge products and innovative solutions from Haitian Group’s diversified businesses—including Haitian Precision, Haitian Drive, Haitian Die Casting, Haitian Smart Solutions, and Haitian Laser Machinery—were also on full display, demonstrating Haitian’s comprehensive industrial portfolio and strong capabilities in the machinery and equipment sector.

In parallel, a series of technical forums were held, bringing together industry experts to explore future trends and technological breakthroughs in plastics processing industry. These sessions provided valuable insights and strong support for the industry’s further development.

Although the 2025 Haitian South China Headquarter Open Week has concluded, the journey Beyond Manufacturing has only just begun. The event not only showcased Haitian’s profound expertise and outstanding achievements in smart manufacturing but also reaffirmed the company’s commitment to working hand in hand with global partners to shape the future of intelligent manufacturing.

As a key pillar of Haitian’s “dual-center” strategy, the South China Headquarter is not only a technological stronghold for smart manufacturing but also an innovation engine for ecosystem collaboration. Going forward, the Haitian South China Headquarter will continue to integrate R&D, production, and talent development, accelerating the transformation of innovation into practical value for customers. Haitian will maintain an open mindset, leverage its solid technological foundations, and strengthen its smart ecosystem, joining hands with global partners to drive innovation and further create more value for the customers and partners.

The post 2025 Haitian South China HQ Open Week Concludes appeared first on 伟德软件下载安装手机版.

]]>